Firmware updates delivers high-definition capabilities to Stratasys Selective Absorption Fusion 3D printing technology

Table Of Content

The obtained geometry was either isotropically (scaled) or anisotropically deformed (pore throat enlargement) in order to replicate the compacted and dissolved pore spaces found in natural specimens. Subsequently, permeability measurements were performed experimentally and numerically, based on those samples. Their results enhanced our insight into the power-law-based porosity-permeability relation for compaction and dissolution, by proposing a fitting coefficient for each case. NTop (formerly nTopology) was founded in 2015 with the belief that engineers’ ability to innovate shouldn’t be limited by their design software. Design for Additive Manufacturing (DfAM) is the methodology of creating, optimizing, or adapting the form and function of a part, assembly, or product to take full advantage of the benefits of additive manufacturing processes. The immediate availability of computer-aided design (CAD) models is also a tremendous benefit to designers.

Firmware update delivers high-definition capabilities to Stratasys Selective Absorption Fusion technology

For mutual customers, these certifications allow the development of innovative and highly differentiated end-products using best-in-class EDA software and industry-leading silicon process and advanced packaging technologies. Sherri Monroe, AMGTA's executive director, emphasized the importance of research and driving informed decisions to foster sustainable manufacturing practices leveraging additive technologies. “These findings highlight key considerations for manufacturers seeking environmentally friendly feedstock production methods. To advance sustainability in additive manufacturing, research is vital in order to make informed decisions,” she said.

Additive Manufacturing for Innovative Design and Production

This book describes how the potential of additive manufacturing can be used specifically in product development to design highly efficient products. For this purpose, the contents are linked holistically in the sense of development processes of product creation. Due to the constraints of traditional manufacturing methods, some complex components are usually separated into several parts for the ease of manufacturing as well as assembly. Some case studies have been done to shows some parts in the original design can be consolidated into one complex part and fabricated by additive manufacturing processes. The research shows parts consolidation will not only reduce part count, it can also improve the product functional performance.[14] The design methods which can guide designers to do part consolidation can also be regarded as a type of DfAM methods.

Additive manufacturing-oriented concurrent robust topology optimization considering size control - ScienceDirect.com

Additive manufacturing-oriented concurrent robust topology optimization considering size control.

Posted: Sat, 15 Jul 2023 07:00:00 GMT [source]

Getting DFAM Help

Today, additive manufacturing has matured to the point where it’s used to produce critical parts that fulfill even the most demanding engineering requirements. This level of maturity is only possible if you take advantage of the core benefits of the technology. Another great resource to learn more about the design consideration of a specific additive manufacturing process or system are their machine operators. Technicians often have a very high level of expertise regarding their machines, so it is always worth asking for advice on your design before committing to a print. To resolve this issue, manufacturers will have to prioritize and invest in their employees' industrial literacy.

There are innovative software out there that can help you design with latticing by automatically generating complex, lightweight parts with lattice structures. The generative software can take your part and organically incorporate latticing within the structure and optimize supports for necessary strength. These design software have grown to accommodate additive techniques, which can allow you to actually design with organic and natural shapes. The ability to 3D print a complex shape means nothing if it takes too long to model it in CAD.

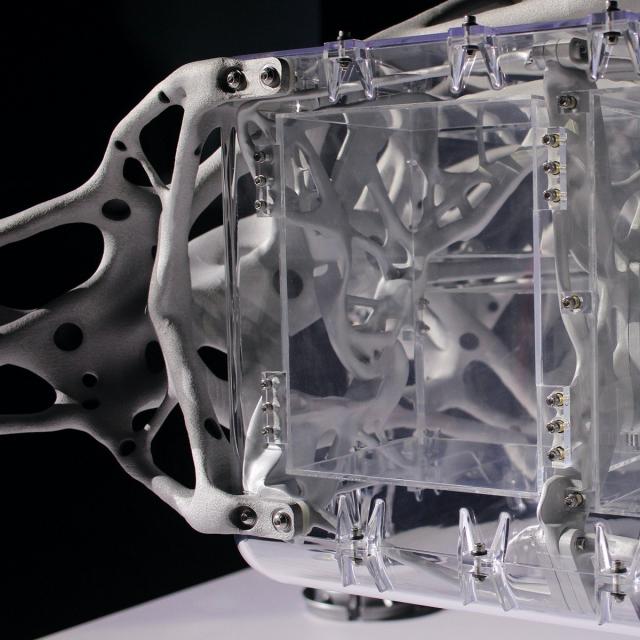

To achieve this, it is essential to ensure that the Capillary number is respected within the domain, and further investigation of the sample wettability is warranted. Specifically, the use of enlarged yet still representative pores in our domain, without sacrificing dimensionality, allows for systematic variations in mean pore size and porosity. This, in turn, allows for effective visualization of scenarios such as the displacement of two different immiscible fluids while accurately tracking the movement of the interface within a realistic and well-validated domain. The representativeness of the printed domains compared to the digital designs is very well demonstrated by a visual comparison of (a) the cylindrical designs shown in Fig. A 3D printed sand casting mold was used to manufacture this 1-meter long topology optimized robotic arm. Its production would be impossible with traditional processes for mold-making and economically prohibitive using metal additive manufacturing technologies.

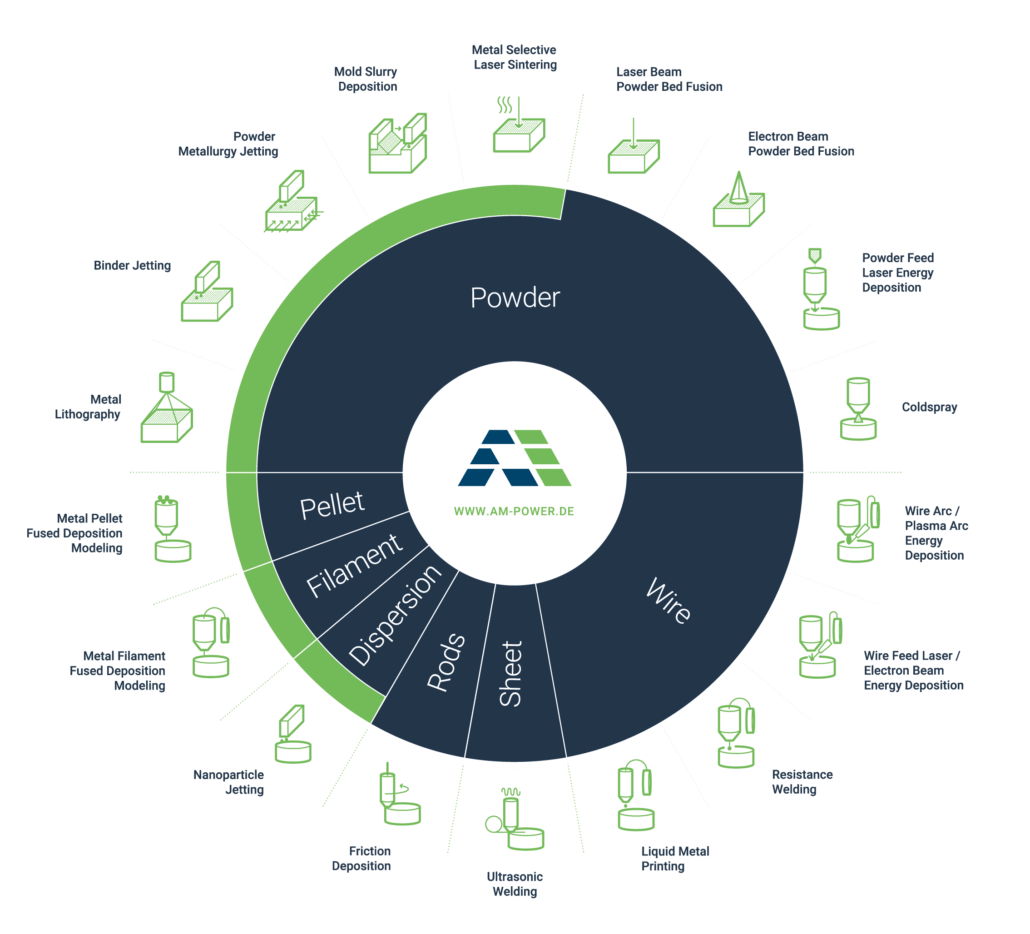

The difference is that binder jetting uses adhesive to bond particles, something which offers a variety in the available printing materials. By depositing the adhesive in a designed pattern layer by layer, a final 3D structure can be obtained27. Although additive manufacturing is a relatively young discipline, the effects that can be achieved with the various additive technologies in terms of efficient product and manufacturing process optimization are of outstanding importance.

However, the limitation was also revealed that the inner structures were fabricated without control thus, making it very challenging to narrow the the gap between the natural rock and the printed sample. In recent years, several of the above described additive manufacturing approaches have been used for the construction of the pore space geometry of three-dimensional, realistic porous media as summarized in Table 1. Such studies mostly focus on the macroscopic properties of porous media, such as the porosity-permeability correlation20,21, and the elastic properties of un-/saturated samples of natural rock proxies28 . Huang et al.28 used Fused Deposition Modeling (FDM) technology with a Stratasys Dimension SST 768 printer to fabricate a cube-shaped porous medium measuring 25 mm on each side. FDM is a 3D printing method that melts a plastic filament and deposits it layer by layer to create a 3D object.

Design for additive manufacturing of plastic injection tool inserts with maintenance and economic considerations: An ... - ScienceDirect.com

Design for additive manufacturing of plastic injection tool inserts with maintenance and economic considerations: An ....

Posted: Tue, 15 Aug 2023 01:59:15 GMT [source]

This is why we teach our learners how to transform their mindset to look at problems from a completely different perspective and then give them the skills to implement those solutions using tools purposely created for additive design. Creating parts and products that are lighter, better performing and potentially cheaper to produce stand out as key advantages of AM. But these possibilities can't easily be realized if your understanding of manufacturing design is rooted in more traditional methods. As such, our program aims to give designers a new perspective — an "additive thinking" mindset. Jabil's research shows that 71% of survey participants choose to work in traditional methods due to a lack of knowledge about how to utilize 3D printing. The skills gap in additive manufacturing is a present challenge that could've originated with widespread misconceptions, such as the assumed difficulty of operating 3D printers.

Figure 13 shows a 3D reconstruction of the scanned micromodels in the same order with respect to \(\lambda _s\) (from left to right), as shown in Fig. The characteristics and the quality of the printed domains with respect to the corresponding digital designs (Fig. 2) are discussed in detail in the “Results and discussion” section. Finally, our experts focused on the concept of lattice structures, which is a form of optimization since it aims to reduce the weight of a part while maintaining its structural integrity. Latticing works by creating a network of meshes and knots that are often compared to a honeycomb structure, a design that is difficult to obtain using traditional manufacturing methods. The advantages of such a design are many, but the main point to remember is that they offer an optimal strength to weight ratio.

"[Thank you] for a very well structured professional course on Additive Manufacturing. Really enjoyed gaining new insights from the course material and from fellow industry professionals." This course uses Autodesk Fusion 360 to share CAD files, structure Graded Activities, and Case Studies, and otherwise provide access to professional-grade engineering tools for course students. Evaluate the business case for transitioning a product to be made using AM versus a conventional approach, either in part or in whole. Design automation finds applications in designing personalized medical devices, such as implants, prostheses, and orthoses. A 12-month program focused on applying the tools of modern data science, optimization and machine learning to solve real-world business problems. Some directions are more efficient than others and may improve strength and build quality.

Due to the absence of this constriction of using a tub with the material, it is possible to use several printing materials. Commonly, a support material is also used in order to prevent the mechanical failure of the structurally weak part. In powder bed fusion, the method is based on the use of a tub of printing material powder. By selectively sintering, or even melting, the corresponding material, the powders bond, and a solid 3D structure can be formed layer by layer. The Binder jetting method also utilizes a bed of powder similar to powder bed fusion.

Sometimes these are used to improve the ergonomics or aesthetics of a product, which is common in consumer goods. Other approaches can elevate the performance and function of a design in more high-tech industries, such as aerospace. This benefit gives a considerable advantage over traditional manufacturing technologies for design optimization. While the basic concepts are easy to understand, their implementation can be challenging to master. The state-of-the-art and best practices are constantly evolving as the capabilities of additive technologies (and engineering design software) continue to advance.

Many examples of such deep-rooted practical impact of DfAM have been emerging in the 2010s, as AM greatly broadens its commercialization. As the industry continues to evolve toward environmentally friendly practices, insights from this research may serve as a resource for manufacturers looking to make informed decisions about feedstock production methods and additive manufacturing. This phase impacts every aspect of a final product, ranging from the part's end-user applications to the cost of its fabrication. An online additive manufacturing course on the fundamentals, applications, and business implications of 3D printing for design and manufacturing. There are several approaches that an engineer skilled in DfAM might use to take advantage of the unique capabilities of AM production.

Comments

Post a Comment