Design for additive manufacturing: 3 levels of DfAM

Table Of Content

Find out how this new approach is an integral part of the industrial 3D printing process and which design tools are at your disposal. A core component of the DfAM method has a lot to do with the product or part's application and function. There is a strong relationship between geometry and performance and planning for it is key to the process. As a result, previously unattainable, highly customized design features like a lattice structure are now available through additive manufacturing. That is because, aside from specific use cases, traditional manufacturing is still faster and less expensive. While the initial units are cheaper and faster when made with additive manufacturing, in the long run, printing out every unit would take longer.

What dictates which DfAM technique is used?

E-learning sessions, live webinars and practical task exercises help you hone your advanced design skills and train you to think additively. We give our learners the choice of focused training on their choice of these three tools in our Additive Manufacturing Design certificate program because each offers different opportunities for key aspects of additive design. With expert guidance and experience included as part of the program, we provide our students with the skills and knowledge to benefit any additive design team. Hence the need for new specialist additive CAD programs that allow designers to create parts differently. Three of the most effective software packages available are nTopology, Altair and Synera.

AM & 3D Printing Supplier Directory

Experimental studies using 2D pore-scale models have also provided valuable insight on the effects of the competition between viscous and capillary forces on the dynamics of the interfaces during also immiscible two-phase flows. In a seminal contribution, Lenormand and coworkers11 have demonstrated the combined effects of the fluid viscosity ratio and the Capillary number of the flow on the evolving field-scale shape of the interfaces. The phase-map developed in this study has been since used for the interpretation of different flow regimes observed in a series of subsequent studies12. These contributions also highlighted the effects of flow history in steady state relative permeability values besides the common dependence on the saturation. Immiscible two-phase flow in porous formations is a classic example of a process where the established continuum approach often fails to appropriately describe flow dynamics in a physically consistent manner under specific flow conditions.

Material Extrusion / Fused Deposition Modeling (FDM)

These processes offer innovative and versatile opportunities for accelerated product design and advanced design and manufacturing process optimization. In addition, the use of nature-based technologies also makes it possible to manufacture components with extreme complexity and internal structures that were very difficult or impossible to produce using conventional methods. Lightweight design and energy savings, also in the product life cycle, can thus be realized with the same stability and load-bearing capacity.

Design to minimize cost

This article will guide you through the various concepts, skills, design methods, and best practices used in state-of-the-art Design for Additive Manufacturing. According to Jabil's survey, 50% of engineers and designers say two of the biggest benefits of 3D printing are the ability to produce personalized and customized goods and deliver them more quickly. With mass adoption of 3D printing, businesses will be closer to customers and can address issues instantly on the assembly line. Tools and fixtures that used to take months to create and customize are now completed in weeks or days, resulting in an 80% time reduction.

Additive Manufacturing Education and Fun at AMUG 2024 - Digital Engineering 24/7 News

Additive Manufacturing Education and Fun at AMUG 2024.

Posted: Thu, 01 Feb 2024 08:00:00 GMT [source]

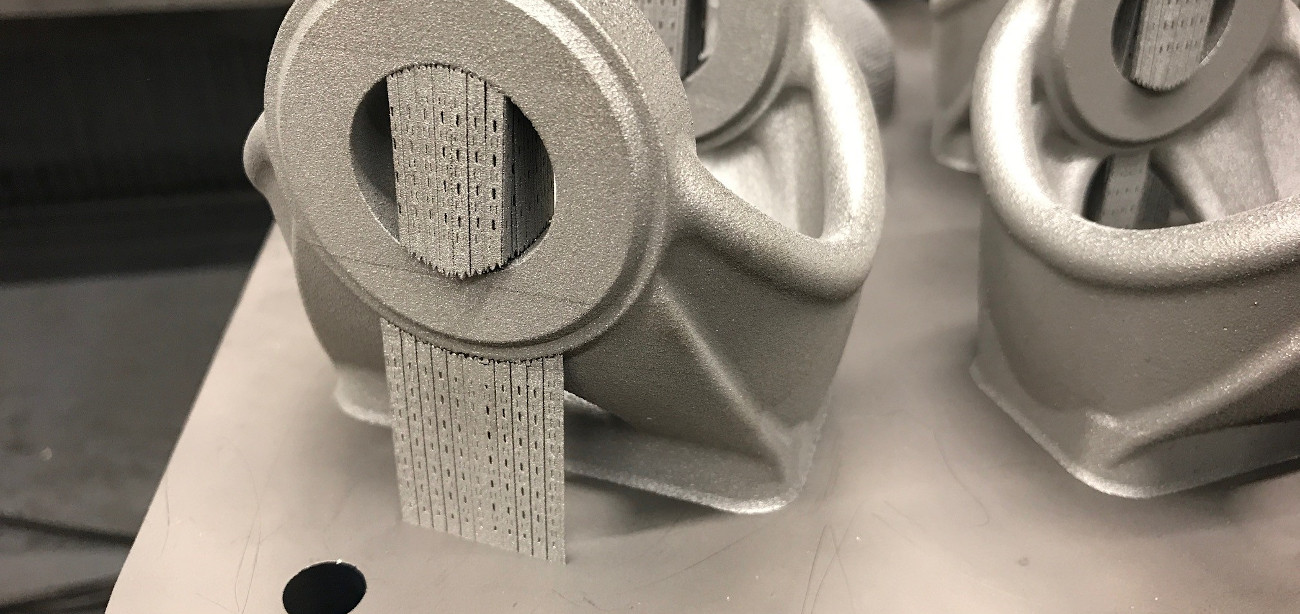

By far, the biggest issue with most manufacturing techniques is the inability to remove material from places that are otherwise unneeded. Designing in lattice structure may be an obvious solution to you, but typical CAD software doesn’t make it easy. Not to mention the manufacturing hurdles you are probably going to have to overcome in the production process. You can quickly and easily incorporate latticing into your selected designs and provide for internal stress analysis and hollowing with these new latticing software. When a component is topologically optimized, it ends up looking far more organic than would be easily-designed in many CAD software.

GKN Aerospace invests in sustainable additive manufacturing - Aerospace Manufacturing and Design

GKN Aerospace invests in sustainable additive manufacturing.

Posted: Thu, 11 Jan 2024 08:00:00 GMT [source]

Although the design methods listed in the previous section form the critical tools in a DfAM engineer's arsenal, a few more steps are needed to ensure that additive production is viable from an economic standpoint. In practice, many components were designed in a certain way due to manufacturing constraints or simply to fit in the available space. By going back to the basic engineering design requirements, you can design components with increased functionality. 4-D printing creates 3-D objects that have the ability to change or transform over time, without human interaction. A commonly cited benefit of additive manufacturing is the ability to consolidate multiple parts into a single one. One notable example is GE’s additively manufactured fuel nozzle for CFM International’s LEAP aircraft engine.

Since the printing method utilizes granules (or powder) and binds them with adhesives, one can fabricate a specimen which contains designed macro pores and micro pores which are shaped by the shape of the granules. Unlike previously mentioned stereolithographic printing methods, this approach could provide a great potential to resolve very fine micro pores while producing final outputs in relatively bigger scales. With many additive techniques, you can actually manufacture more complex parts than are capable of being designed within software. Through many additive software, you can automatically pinpoint areas where material is unnecessary, and either remove it altogether or easily replace it with a complex lattice structure. AM isn’t just about increasing the time you can spend on design, it’s about being able to manufacture beyond what you can currently easily design.

As engineers, we may like to think of 3D printing as rapid prototyping, but on a large scale, additive is usually much slower than other manufacturing processes. Many additive techniques can also require post-processing after printing, which further increases production time. Generative design is exactly that, and through additive manufacturing, it can become a relatively easy reality. There are many generative design programs where engineers can input constraints and the software will develop organic and perfected structure. The generative design software iterates each design automatically until the generated structure is organically perfect for your design needs. By saving time and money, boosting creativity, and integrating beautiful geometry, generative design may be exactly what you need to impress your boss.

Additive manufacturing is rapidly growing into a revolutionary engineering technology that has the ability to completely shift our design methodologies. While AM isn’t perfect for every project, it may be good to consider for some of the more technically complex projects you are working on. Some forms of additive are naturally going to be more expensive, or even time consuming, but the customizable benefits and design focusing aspects can make it a viable option.

In addition to being limited to solid components, you are also limited by shapes and designs of parts to allow for mold separation. However, what if you don’t need a solid structured part or need one with a complex shape? With previous forms of manufacturing, you would be kind of stuck; but not with additive. The research emphasizes that helium gas atomization emerges as t method for metallic powder production among gas atomization techniques for commonly used alloys.

Different from traditional manufacturing, this additive design process empowers engineers to create more intricate shapes and production parts while reducing weight and material consumption. In fact, almost 60% of 3D printing stakeholders at companies worldwide said additive manufacturing has already changed the way they think and operate, according to Jabil's recent survey. Utilizing the DfAM approach offers more design freedom, part consolidation, as well as time and cost savings.

Nonetheless, the name "DfAM" has value because it focuses attention on the way that commercializing AM in production roles is not just a matter of figuring out how to switch existing parts from subtractive to additive. Rather, it is about redesigning entire objects (assemblies, subsystems) in view of the newfound availability of advanced AM. That is, it involves redesigning them because their entire earlier design—including even how, why, and at which places they were originally divided into discrete parts—was conceived within the constraints of a world where advanced AM did not yet exist. The object thus may no longer be an assembly at all, or it may be an assembly with many fewer parts.

Additive manufacturing is suited to low-volume, complex components, and thus careful consideration should be given to the selection of this technology over traditional manufacturing technologies. Product design considerations such as build orientation and support structures will be presented which affect manufacturing cost and time, post-processing requirements as well as mechanical properties of the final component. Some case studies will be presented at the end of this chapter which use additive manufacturing to produce lighter, more geometrically complex or consolidated products. It enables the fabrication of parts with a complex shape as well as complex material distribution.[5] These unique capabilities significantly enlarge the design freedom for designers.

Comments

Post a Comment